Overview: The COVID-19 pandemic has squeezed supply chains around the globe. Companies involved in the supply chain have needed to develop new methods up and down the supply chain, from AI managing the entire system to new vehicles for delivery and pickup.

What Happened To The Supply Chain?

One innovation revolutionized how we buy things in the 1990s – “just-in-time” management. Before just in time, any manufacturing facility needed to keep a stock of both raw materials and parts on hand. As well as a stock of finished products, taking up space and capital that could be better spent elsewhere.

Just-in-time management instead developed systems where the parts and raw materials show up right when you needed them. This innovation has reduced waste, increased product quality, and drive down the prices consumers and wholesalers alike pay for everything we buy.

Yet, the COVID-19 pandemic demonstrated how uniquely vulnerable it is to specific shocks. As shutdowns rolled across the globe, factories went dark. When the shutdowns lifted, it became clear that the human toll of the pandemic was hitting the economic side as well. With fewer workers available, and many worried about the risk of getting sick, delays and shortages have cascaded throughout the global supply system.

It’s less a case of bottlenecks and more a situation in which a formerly broad channel has suddenly been tightened, while the same demand pulls through at the other end. Adding to the constriction is that eCommerce and other businesses reliant on shipping and logistics have boomed during the pandemic, drawing workers away from manufacturing and towards logistics.

And in turn, this has meant innovation strategy has suddenly become front and center. Where any delay cascades through a system, this has made innovation fundamental to supply chains. Here are five areas in which this is happening.

1. Big Data and AI

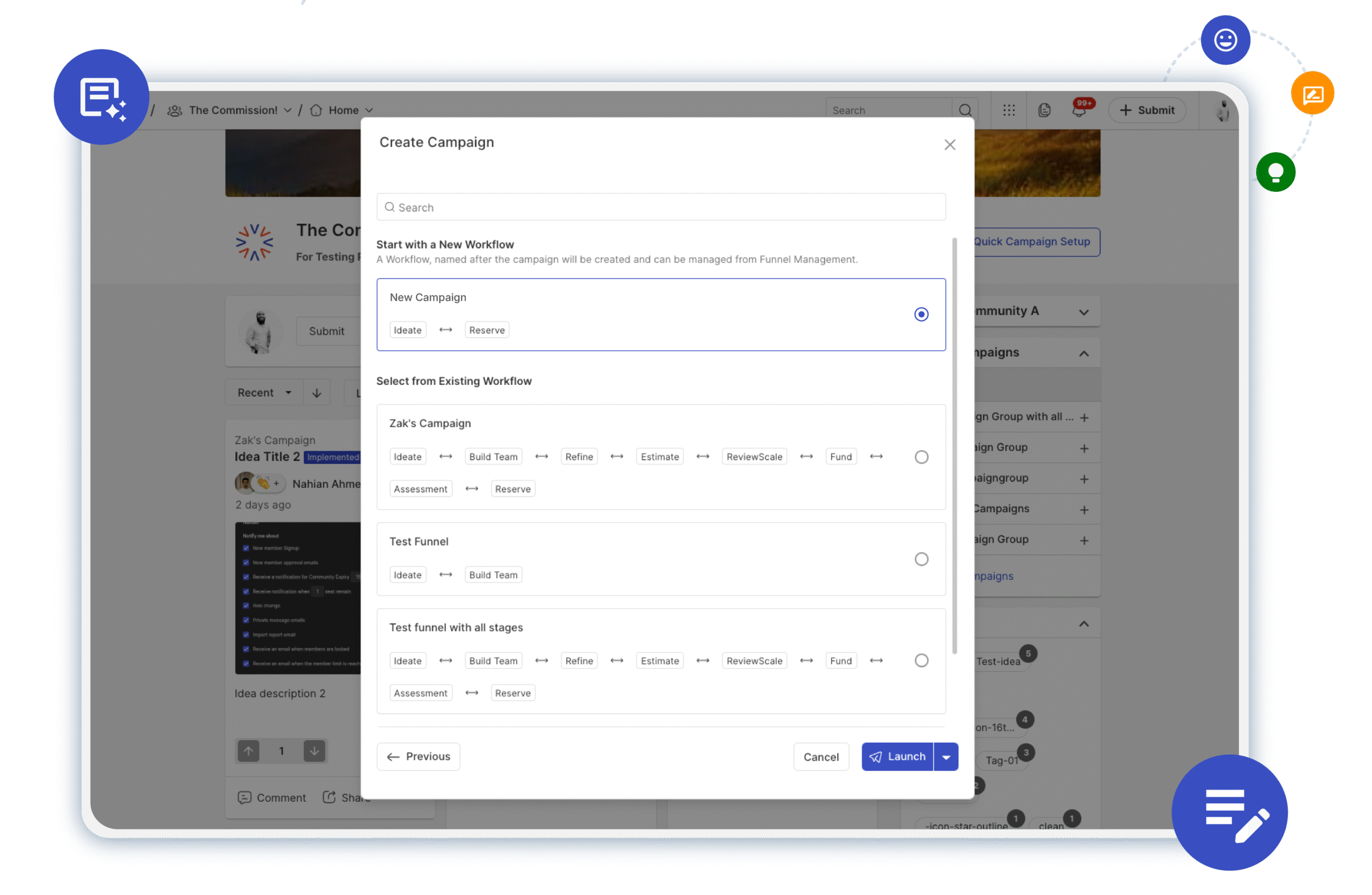

Data science and artificial intelligence had been part of the logistics industry well before the pandemic. It’s vital to understand that the primary goal of AI in this scenario is to analyze data and draw out patterns for humans to review.

Pre-pandemic, and particularly during, the key role was to anticipate demand and get ahead of potential runs on products. Yet, the use of AI has accelerated during the pandemic to help keep people six feet apart, taking over jobs as diverse as inspecting ships for damage to predicting the possible risk of infection among the crew.

Going forward, this will help ease bottlenecks by anticipating problems and catching errors before they can roll through the system.

2. Geolocation

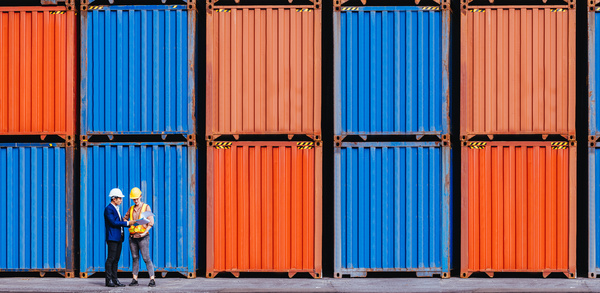

It’s not well known, but the modern shipping industry owes its existence to the U.S. Department of Defense and the Vietnam War. The DoD needed to ship thousands of tons of supplies quickly and efficiently, setting the stage for containerization to take over the global shipping industry.

The Department of Defense has similarly been leading the way in logistics, particularly with geolocation and tracking. For example, the DoD has pioneered RFID tracking technologies to track high-value assets and assist with transporting them across vast distances.

During the pandemic, this has helped in ways both obvious, such as tracking shipments, and less so, such as giving customers a method to directly check where their order is on a ship. The transparency of geolocation helps answer multiple questions at once while generating more data for AI to use as new logistics concerns arrive.

3. Augmented Reality

While the fad for consumer smart glasses may have passed, the need for augmented reality in the logistics workplace has only become more intense. Smart glasses allow workers to scan barcodes by glancing at them, receive data and instructions directly through their glasses, collect picking information, and document their work without needing to halt for paperwork or to fill out forms. They can even substitute traditional eye protection in some scenarios, solving two issues at once.

This has both made workers more productive and improved their quality of life. New workers need less training, and more seasoned employees are grateful to leave the clipboards behind.

4. Robotics

Robots have been involved in logistics for years, picking orders, assisting workers, and generally helping to keep warehouses and other logistics facilities running. During a supply chain squeeze, however, they’ve become invaluable for other reasons.

For example, robots can guide new employees to the right areas for picking work, saving time for managers, and preventing people from getting lost in what are increasingly cavernous facilities. Similarly, robots can serve as a helping hand during the picking process, rapidly expediting picked orders and returning for more.

And, of course, robots are still taking over “3D” tasks, short for dirty, dangerous, or demeaning. Even having a robot clean the floor instead of an employee frees up needed time to get orders out the door.

5. Last-Mile Shipping

Of course, amid all of this, it’s the “last mile” that’s been the most challenging. Getting packed and shipped orders to customers has been difficult as logistics companies fight food delivery apps, rideshare companies, and eCommerce operations for workers.

Some of this innovation has taken the form of vehicles. Electric bikes, for example, are becoming increasingly popular, especially in cities with narrow streets or complex layouts. On-demand warehousing has meant space can be reserved for big shipments closer to where they need to go out.

And in some cases, logistics companies are taking their cue from Starbucks. With some orders, customers have been given the tools to simply request their order be held through an app, and they come by to pick it up in classic post office style. Some companies are encouraging this for smaller orders, while others are throwing it open to everyone interested to save room on trucks.

It’s not clear when the supply chain issues will ease. The pandemic is still unfolding in many parts of the world. And, in some cases, industries are considering relocating entire supply chains closer to factories or even investing in making their own parts.

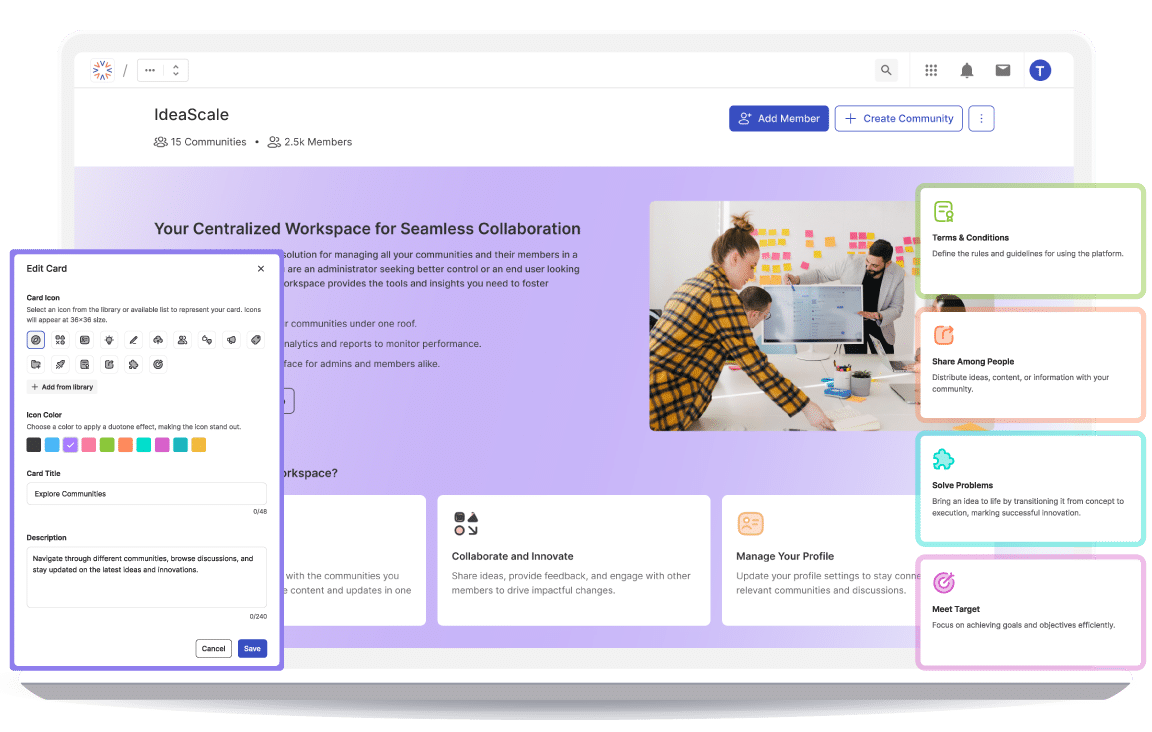

Most Recent Posts

Explore the latest innovation insights and trends with our recent blog posts.